|

04-06-2017, 08:19

04-06-2017, 08:19

|

#1

|

|

Registered User

Join Date: Sep 2012

Posts: 54

|

5086-H116 Aluminum Frames

Good Morning to All! I in search of Help with an Aluminum Catamaran Boat configuration. I have been learning a few things in Fusion 360, if I could I would use Rhino 3D, but that's a pretty penny. Naval Architects seem hard to talk to about my ideas and people in general criticism the idea more then guiding me towards the right answer. Where I'll like to be in this plan is finding out the thickness of the frames to this Catamaran. Length: 7X12 Meters. Where I am at. Spacing from one frame to another is 60cm, plates 5-6mm thick. 5052 H32 plates could be used on the sides. Welding wire is 5356 Gage: .030. MIG Gas: 75/25. Now I gotta tell you, I am stubborn!! so please don't tell me it's impossible. With everyone's help I will be able to build this boat . Thank You for your Support.

|

|

|

04-06-2017, 11:33

04-06-2017, 11:33

|

#2

|

|

Moderator

Join Date: Jul 2007

Boat: Bestevaer.

Posts: 14,678

|

Re: 5086-H116 Aluminum Frames

Thiago it sounds like you have tons of tenacity, grit and gumption. These qualities are incredibly important in a home build, but, and I cannot stress this enough, a boat has to be well designed. This is especially true of a cat. With a mono the structure can be overbuilt, but not a cat.

You can design the interior and construct it yourself, you can design the systems such as electrics and plumbing and install these systems. You can fair and paint. You can rig the mast and even sew the sails.

Designing the hull structure is not a job for amateurs. In any case you will need cutting files so a proffesional designer is needed.

5052 has not much to recommend it, other than it is cheaper. Stick with the better alloys.

If it is any help, and I am not sure it is, this is our 50 foot mono under construction. In many ways a 50 foot mono can be compared to a 40-43 foot cat so the vessels are not totally dissimilar, but this similarity does not extend to the construction which on an equivalent cat will be lighter due to the need for weight saving. The load paths are also very different.

The skins on our new boat are 10 and 8 mm the framing is mostly 8 and 6mm thick with thicker sections for the keelson, mast support, rudder etc. These are up to 20mm thick.

On your cat I would expect the skins to be commonly 4-6mm on the bottom, reducing to 3-4 mm for the topsides. The framing will be deep and closely spaced. T or L section profiles sections, typically 4-5mm.

|

|

|

04-06-2017, 11:45

04-06-2017, 11:45

|

#3

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: 5086-H116 Aluminum Frames

Quote:

Originally Posted by thiago1979

Good Morning to All! I in search of Help with an Aluminum Catamaran Boat configuration. I have been learning a few things in Fusion 360, if I could I would use Rhino 3D, but that's a pretty penny. Naval Architects seem hard to talk to about my ideas and people in general criticism the idea more then guiding me towards the right answer. Where I'll like to be in this plan is finding out the thickness of the frames to this Catamaran. Length: 7X12 Meters. Where I am at. Spacing from one frame to another is 60cm, plates 5-6mm thick. 5052 H32 plates could be used on the sides. Welding wire is 5356 Gage: .030. MIG Gas: 75/25. Now I gotta tell you, I am stubborn!! so please don't tell me it's impossible. With everyone's help I will be able to build this boat . Thank You for your Support. |

puzzled . . . your title says 5086 H116 - which is fine alloy for yacht construction (along with 5083); but your post says 5052, which is less appropriate (5052 is often used on fuel tanks). Which is it? We used both 5086 H113 and 5083 H113 in our build, and a much more specialized alloy for the rudder shaft.

60cm frame spacing is generally quite acceptable, might tighten it a bit up a bit in particularly high load areas (chain plates, etc). Our design called for 60cm spacing, 50mm deep T shaped . . . .we deepened them to 75mm, closed the spacing a bit in high load areas (mast, chainplates, rudder, keel front and back edges, and cutwater/forefoot area) . . . but we were a mono and not too concerned about weight.

6mm is also generally quite acceptable for skin thickness, with thinner on the decks. For a multi I think that is probably about right.

But I not exactly sure what is your question?

|

|

|

05-06-2017, 02:19

05-06-2017, 02:19

|

#4

|

|

Registered User

Join Date: Sep 2012

Posts: 54

|

Re: 5086-H116 Aluminum Frames

Here is a general idea of a frame. Now this is not by any means a direct result of a hull actual form.

|

|

|

05-06-2017, 02:50

05-06-2017, 02:50

|

#5

|

|

Registered User

Join Date: Sep 2012

Posts: 54

|

Re: 5086-H116 Aluminum Frames

Here is what I understand so far. 5mm vertical frames. 600mm horizontal spacing. I think the 400mm vertical spacing may be around what other frames are, but not sure. The 10mm cross bars is an unknown thickness as well. I am trying to find the average specing and thickness of the Square.

|

|

|

05-06-2017, 03:34

05-06-2017, 03:34

|

#6

|

|

Registered User

Join Date: Sep 2012

Posts: 54

|

Re: 5086-H116 Aluminum Frames

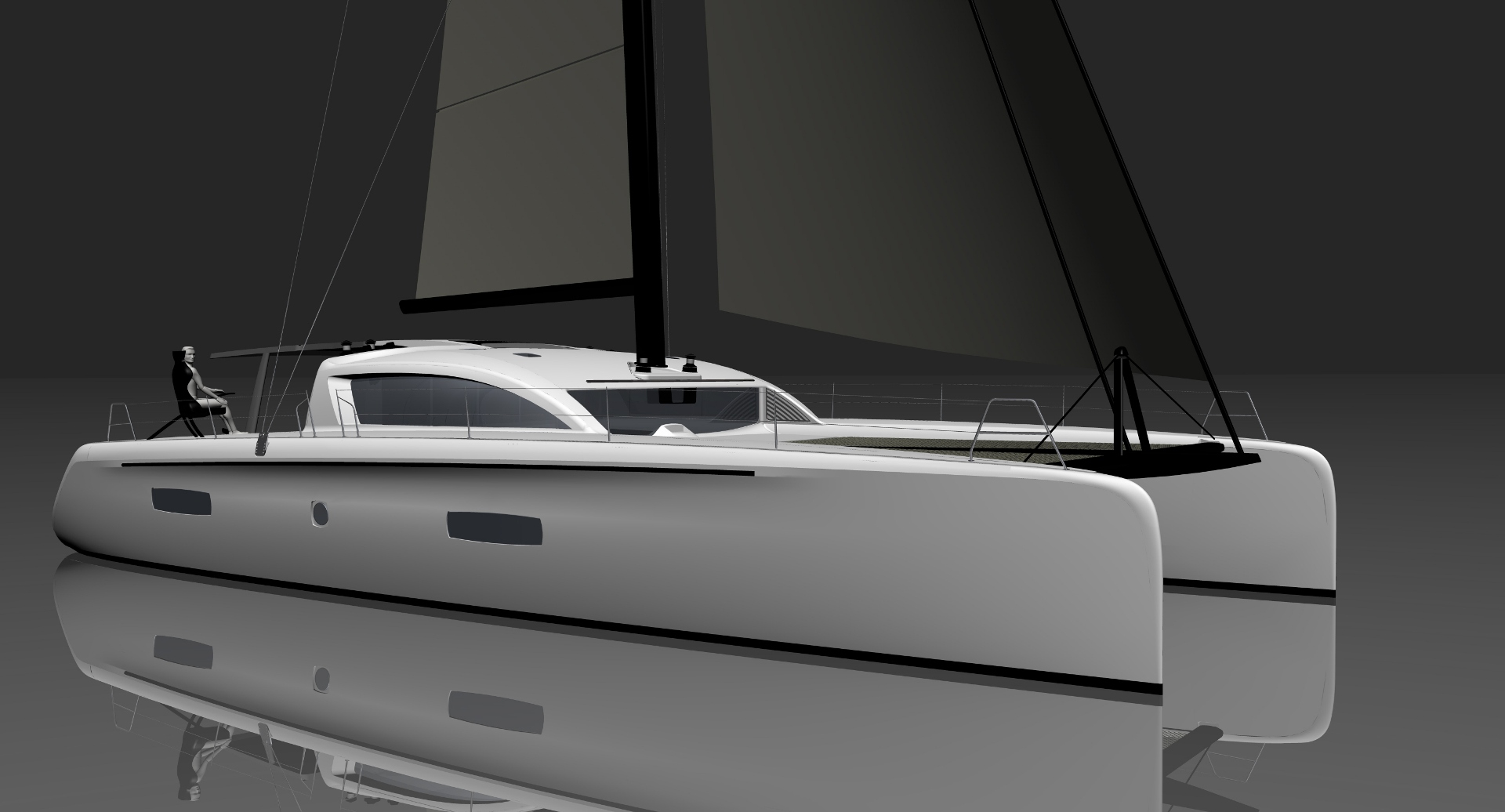

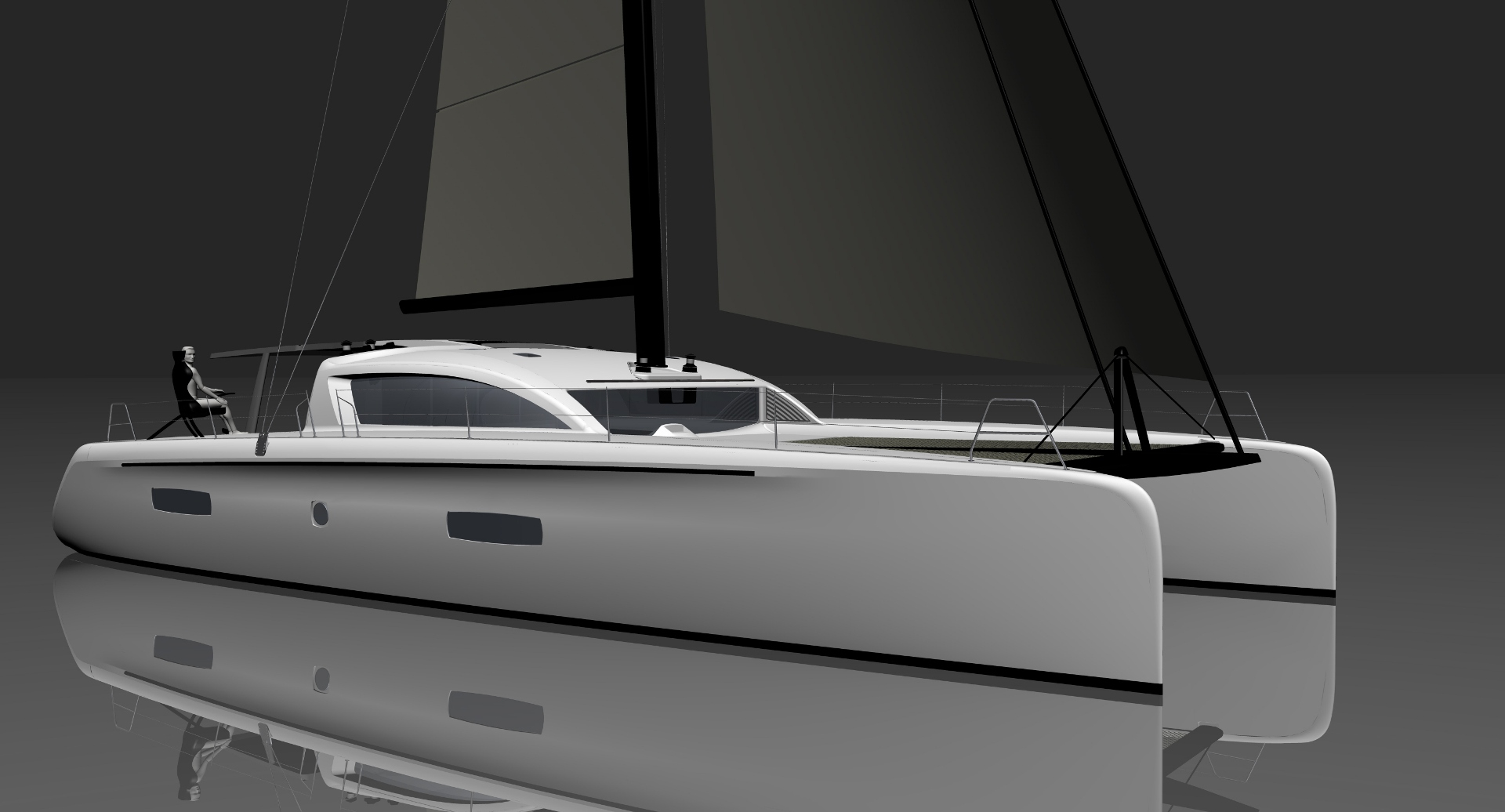

Thank you for your time noelex 77! By the way, beautiful frame work! Right now I posted a few pics so you guys can see what I am up to. I agree in regards of seeking a Naval Architect to look over and change things in regards to Buoyancy and over all stability and performance.

|

|

|

05-06-2017, 03:49

05-06-2017, 03:49

|

#7

|

|

Registered User

Join Date: Sep 2012

Posts: 54

|

Re: 5086-H116 Aluminum Frames

Quote:

Originally Posted by estarzinger

puzzled . . . your title says 5086 H116 - which is fine alloy for yacht construction (along with 5083); but your post says 5052, which is less appropriate (5052 is often used on fuel tanks). Which is it? We used both 5086 H113 and 5083 H113 in our build, and a much more specialized alloy for the rudder shaft.

60cm frame spacing is generally quite acceptable, might tighten it a bit up a bit in particularly high load areas (chain plates, etc). Our design called for 60cm spacing, 50mm deep T shaped . . . .we deepened them to 75mm, closed the spacing a bit in high load areas (mast, chainplates, rudder, keel front and back edges, and cutwater/forefoot area) . . . but we were a mono and not too concerned about weight.

6mm is also generally quite acceptable for skin thickness, with thinner on the decks. For a multi I think that is probably about right.

But I not exactly sure what is your question? |

5086-H116 Aluminum Frames and plates is what I would use. My main focus is the Square. Spacing and thickness of both Horizontal and Vertical Frames. Plates are more easily discussed and generally are around 5-7mm thick. Since Plates are more easily agreed thickness and material 5086-H116, I am placing my doubts more on the correct Box dimension in witch I call it the square. To find the correct and most used spacing and thickness. Thanks for your Support.

|

|

|

05-06-2017, 04:59

05-06-2017, 04:59

|

#8

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: 5086-H116 Aluminum Frames

lets back up a little for a moment . . . . .

what are your objectives here? I presume you know that an aluminum cat is going to be heavier than a similarly well built composite cat, so I presume you are not going for 'light as possible' - what are you trying to accomplish? Is this basically going to be a cruising houseboat? What do you intend to do with it, and where you intend to take it? Those questions should affect the structural design - you can 'over build' it with one set of answers but need to be more more careful with another set of answers.

Second, your 'square' is pretty typical for unstressed mono hull skin area - probably be fine. There are several of trade-offs between skin thickness and framing - just two for example . . . . . thicker skin allows few frames and is more puncture and corrosion resistance but is heavier; closer/deeper ring frames allow fewer/no longitudinal and reduces potential for water/corrosion pockets inside the hull but is a harder to get skin smooth (all rings and no longitudes is preferred on steel boats, more rings used by Euro designers and more longitudes used by US designers typically). So how exactly to do it does depend on what exactly you are trying to accomplish . . . . .but as I said, the 'square' you have now is reasonably typical for an unstressed area in a smallish yacht.

However, that is the very simplest part of the structure design. the real engineering question is how to structure the stressed areas - on a multi that includes/adds especially the cross beam connections, which is where they fatigue and fail most often. Neither I nor noelex (I suspect) is going to be able to help you with that (we are both mono-hull guys). Again, if you are happy going heavy, you just overbuild the **** out of these stressed areas (put in really big close spaced ring frames in heavier plate and hope it is good) but if you are trying to keep it light that is not going to be satisfactory.

Do you have an idea how you are going to connect the hulls? There are quite a number of fundamentally different techniques/structures to do it, and a few fundamentally different philosophies (totally rigid or some flexibility, disassembly to inspect/fix fatigue or 'permanent', two or three main beams or load spread over wide area). Are you going to have the 'living area' in the hulls with minimal between them, or are you going for the big deck saloon/huge living area between hulls concept?

|

|

|

05-06-2017, 06:50

05-06-2017, 06:50

|

#9

|

|

Registered User

Join Date: Sep 2012

Posts: 54

|

Re: 5086-H116 Aluminum Frames

Quote:

Originally Posted by estarzinger

lets back up a little for a moment . . . . .

what are your objectives here? I presume you know that an aluminum cat is going to be heavier than a similarly well built composite cat, so I presume you are not going for 'light as possible' - what are you trying to accomplish? Is this basically going to be a cruising houseboat? What do you intend to do with it, and where you intend to take it? Those questions should affect the structural design - you can 'over build' it with one set of answers but need to be more more careful with another set of answers.

Second, your 'square' is pretty typical for unstressed mono hull skin area - probably be fine. There are several of trade-offs between skin thickness and framing - just two for example . . . . . thicker skin allows few frames and is more puncture and corrosion resistance but is heavier; closer/deeper ring frames allow fewer/no longitudinal and reduces potential for water/corrosion pockets inside the hull but is a harder to get skin smooth (all rings and no longitudes is preferred on steel boats, more rings used by Euro designers and more longitudes used by US designers typically). So how exactly to do it does depend on what exactly you are trying to accomplish . . . . .but as I said, the 'square' you have now is reasonably typical for an unstressed area in a smallish yacht.

However, that is the very simplest part of the structure design. the real engineering question is how to structure the stressed areas - on a multi that includes/adds especially the cross beam connections, which is where they fatigue and fail most often. Neither I nor noelex (I suspect) is going to be able to help you with that (we are both mono-hull guys). Again, if you are happy going heavy, you just overbuild the **** out of these stressed areas (put in really big close spaced ring frames in heavier plate and hope it is good) but if you are trying to keep it light that is not going to be satisfactory.

Do you have an idea how you are going to connect the hulls? There are quite a number of fundamentally different techniques/structures to do it, and a few fundamentally different philosophies (totally rigid or some flexibility, disassembly to inspect/fix fatigue or 'permanent', two or three main beams or load spread over wide area). Are you going to have the 'living area' in the hulls with minimal between them, or are you going for the big deck saloon/huge living area between hulls concept? |

The main purpose of this Catamaran is to travel international. This will be my life's work as I have no intentions of settling in a typical house in your friendly neighborhood hill. "Home is where you make it". I have long been attracted to this independence. I know there's much to do, this is why I am here to seek advise from all who care and understand that what I am trying to achieve is not just a boat, but my home and refuge to my days end if life permits me so. I'll seek every information I possibly can, here there anywhere I can have a somewhat straight forward blueprint ready to be sent to any Metal Company that can produce the frames so I can begin to work on them. Now these are simple questions I have been asking, so far I have not sit down with a Marine Architect. What I want is that this Blueprint be solely mine. You asked how am I going to place the two hulls together. There's a Cat that is built in three separate parts. the two hulls and the Cabin. There's like a 35 to 45 Degree angle cut right on the hulls that you can weld them together. Attaching the hull to the Cabin. Please see Attached Picture. The Catamaran that I have chosen to have somewhat the looks of it is the Outremer X5.

This is a beautiful frame.

|

|

|

05-06-2017, 07:23

05-06-2017, 07:23

|

#10

|

|

Moderator

Join Date: Jul 2007

Boat: Bestevaer.

Posts: 14,678

|

Re: 5086-H116 Aluminum Frames

Alumarine have produced a number of aluminium cats. Garcia have also released a couple of catamaran models, but they are quite new. If you can get some details of these boats it will give you a starting point. However, I would very strongly urge you to have some professional design input. When building a catamaran there is a fine line between something that is acceptable weight wise and something that is strong enough to survive the rough and tumble of cruising life.

Also note that modern aluminium boats are built from cutting files. This enables the parts to be computer cut so they fit together perfectly. Building from blueprints is harder and the end result is not as good. Unless you have a lot of computer expertise you will need a designer to produce these cutting files or at least pay someone to digitise your blueprints.

|

|

|

05-06-2017, 14:19

05-06-2017, 14:19

|

#11

|

|

Registered User

Join Date: Jul 2012

Location: Hobart

Boat: Alloy Peterson 40

Posts: 3,919

|

Re: 5086-H116 Aluminum Frames

http://eastoncats.tripod.com

These boats are very cleverly designed for the home builder and are well proven. Two freinds have built them and the way they are thought out from a construction point of veiw is very clever, almost self jigging, using the topside panels as the building frame.

I think they used 3 and 4mm plate for the most part. 6mm plate seems too heavy for a 40-45 foot multi?

|

|

|

05-06-2017, 15:02

05-06-2017, 15:02

|

#12

|

|

Moderator

Join Date: Jul 2007

Boat: Bestevaer.

Posts: 14,678

|

Re: 5086-H116 Aluminum Frames

Quote:

Originally Posted by Snowpetrel

I think they used 3 and 4mm plate for the most part. 6mm plate seems too heavy for a 40-45 foot multi?

|

Yes. I think these are more typical numbers for a cat, although you cannot look at skin thickness alone. You need to consider the framing.

3mm is relatively easy to weld, but it is difficult to weld without inducing distortion (although to a certain extent it can be done). This is one of the problems of constructing relatively small cats (say under 45 feet) from aluminium. If looks are important, it is easy with an unskilled builder to end up with a lot of filler, which can be heavier than using slightly thicker plate. 4-5mm is the easiest overall for construction. 6mm and above becomes difficult to bend into complex curves (although it can be done). If the boatyard are very skilled they can overcome these problems.

Here is sample of a skin thickness of 25mm. Amazing, but not a great choice for your cat  .

I think the suggestion to go for a proven design is a very sound one. You can design the interior and system engineering so the vessel will still be essentially a custom project built with your own requirements in mind, but with a hull that is professionally designed.

|

|

|

05-06-2017, 19:05

05-06-2017, 19:05

|

#13

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: 5086-H116 Aluminum Frames

Quote:

Originally Posted by Snowpetrel

I think they used 3 and 4mm plate for the most part. 6mm plate seems too heavy for a 40-45 foot multi?

|

It again comes back to his intentions . . . . my take away was that he wanted a safe home he could live on and potentially cross oceans with, rather than a planing rocket ship. I personally think 6mm is going to fill that mission better than 3 or 4 - but it is certainly open for debate (and there are mig issues we have not discussed).

We were friends with a German couple who were down south with us. They had a 45' (ish) timber cat - it was heavy (ish) - I think the same displacement as Hawk, and they built it that way intentionally. It was a 'full displacement' cat, made the same sort of miles as a similar size mono, had the lovely deck saloon that cats can have and a lot of stability with (relatively) shallow draft, and able to carry a good payload. Seemed a rare set of trade-offs but pretty decent for real world cruising. That is sort of where I see this guy heading from his comments . . . but perhaps I am mistaken.

noelex, btw, most decent 3d cad programs can generate cut files if the surface is develop-able. And cat hulls do usually have much less gaussian curvature than hulls like yours. If it is not develop-able then you do need a more specialize add-on module to do it.

|

|

|

05-06-2017, 19:19

05-06-2017, 19:19

|

#14

|

|

Registered User

Join Date: Dec 2016

Boat: Pearson 33-2

Posts: 375

|

Re: 5086-H116 Aluminum Frames

I didn't read every reply, so apologies if this is redundant.....

.030 is a real bear to MIG aluminum of any thickness with, and running 75/25 gas, it's impossible. You need 100% argon to get started.

|

|

|

|

| Thread Tools |

Search this Thread |

|

|

|

| Display Modes |

Rate This Thread |

Linear Mode Linear Mode

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Advertise Here

Recent Discussions Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vendor Spotlight Vendor Spotlight |

|

|

|

|

|

|

|

|

|

.

.

Linear Mode

Linear Mode

Recent Discussions

Recent Discussions