|

|

14-08-2014, 05:18

14-08-2014, 05:18

|

#76

|

|

Marine Service Provider

Join Date: Jan 2007

Location: Maine

Boat: CS-36T - Cupecoy

Posts: 3,197

|

Re: To Solder or Not.. That is the Question

Quote:

Originally Posted by goboatingnow

If we invested in decent crimps and tooling, it would be immediately obvious that these method is generally superior in handling flexible stranded cable connections. But in practice the average boater simple;y cannot bring himself to splurge on tooling, often to perform only a few connections. Hence the belief in solder, heat shrink etc.

Bad practice is bad practice, but often its the only means at someones disposal.

dave

|

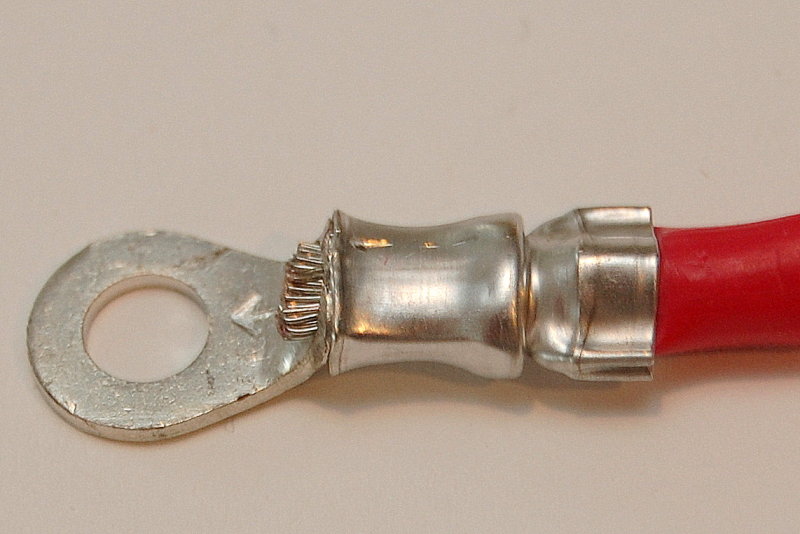

AMP PIDG terminal crimped with AMP crimp tool. This crimp far exceeds the UL 486A, NASA 8739-4 and Mil-T-7928 standards. NASA and Mil-T-7928 are the most stringent I know of...

Good enough for NASA, Boeing and the US Military, good enough for me...

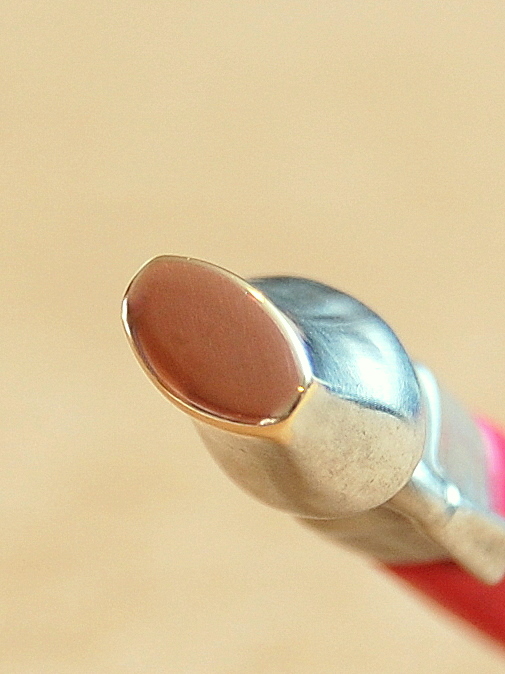

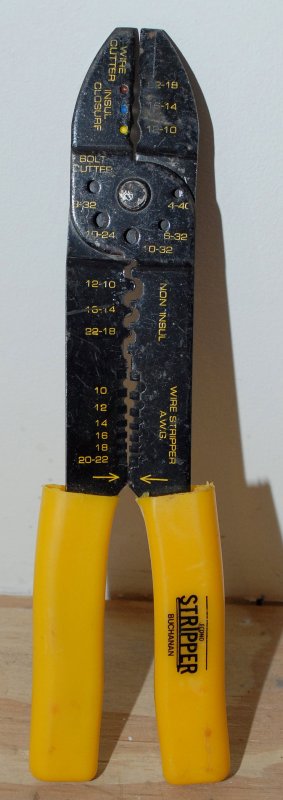

Sadly most expect a tool like this to work the same as the tool above. Not going to happen....

|

|

|

14-08-2014, 07:02

14-08-2014, 07:02

|

#77

|

|

Registered User

Join Date: Jan 2014

Location: Martinique

Boat: Fortuna Island Spirit 40

Posts: 2,298

|

Re: To Solder or Not.. That is the Question

Mainsail - while I respect all your posts....

Holy crap you just recommended a $280 wire crimper. It may be the best, but there is no way I could spend that kind of money on a crimper unless I was a professional.

Any options that are more affordable for mere mortals? Maybe like $80.

Sent from my Nexus 4 using Cruisers Sailing Forum mobile app

|

|

|

14-08-2014, 07:08

14-08-2014, 07:08

|

#78

|

|

Registered User

Join Date: Aug 2012

Location: Hingham, MA

Boat: Catalina 310

Posts: 637

|

Re: To Solder or Not.. That is the Question

Quote:

Originally Posted by travellerw

Mainsail - while I respect all your posts....

Holy crap you just recommended a $280 wire crimper. It may be the best, but there is no way I could spend that kind of money on a crimper unless I was a professional.

Any options that are more affordable for mere mortals? Maybe like $80.

Sent from my Nexus 4 using Cruisers Sailing Forum mobile app |

He already has. Check out Crimper Shoot Out/Load Test Results.

|

|

|

14-08-2014, 07:19

14-08-2014, 07:19

|

#80

|

|

Registered User

Join Date: May 2011

Location: San Diego CA

Boat: Liberty 458

Posts: 2,205

|

Re: To Solder or Not.. That is the Question

Quote:

Originally Posted by travellerw

So... I came across some information recently that shocked me.

The ABYC does not allow solder as the sole means of electrical connections (funny even NASA supports this). Further research then showed that most people do not solder and simple rely on crimped style connections.

This seems to go against all my experience in other industries (automotive, small engine, ATV). When I make connections (especially on an ATV) I will crimp the connection, then solder, then cover with "sealed" shrink tube and finally cover with longer shrink tube (non sealed) for strain relief. Been using this method for 5 years or so and have never had a single failure (in 1000s of connections). I can only imagine that an ATV would be a harsher environment then a boat. Those connections are subject to high vibration due to high engine RPM, plus continual dunking in nasty liquids (marsh/bog water).

I've had some people comment that I "go to far" when it comes to connections, but I disagree. Anyone that has chased down an electrical fault will know what I mean. The time and heartache is worth spending a little time making sure the connections I make are bulletproof.

So my question to you... Do you solder? Do you use "sealed" shrink tube?

and a bonus question... Do you use tinned wire? |

Going to far is much better than not enough. Layers of heat shrink to minimise the stress concentration and to limit the strain is good practice.

There is certainly a school of thought that solder is bad. I'm yet to see anyone who has produced good soldered joints when no other options were available be in this camp.

Solderless joints were developed to be more efficient and consistent than soldered joints. Solderless joints were also needed because high volume industries preferred to use unskilled labor on production lines.

I personally have only had issues with automated solder joints in 30 years. I've had many more issues with poorly crimped joints. At the end of the day making good joint an require an skill and attention to detail.

Sent from my GT-I9300 using Cruisers Sailing Forum mobile app

|

|

|

14-08-2014, 07:20

14-08-2014, 07:20

|

#81

|

|

Registered User

Join Date: May 2011

Location: San Diego CA

Boat: Liberty 458

Posts: 2,205

|

Re: To Solder or Not.. That is the Question

Quote:

Originally Posted by leftbrainstuff

Going too far is much better than not enough. Layers of heat shrink to minimise the stress concentration and to limit the strain is good practice.

There is certainly a school of thought that solder is bad. I'm yet to see anyone who has produced good soldered joints when no other options were available be in this camp.

Solderless joints were developed to be more efficient and consistent than soldered joints. Solderless joints were also needed because high volume industries preferred to use unskilled labor on production lines.

I personally have only had issues with automated solder joints in 30 years. I've had many more issues with poorly crimped joints. At the end of the day making good joints requires skill and attention to detail.

Sent from my GT-I9300 using Cruisers Sailing Forum mobile app |

Sent from my GT-I9300 using Cruisers Sailing Forum mobile app

|

|

|

14-08-2014, 07:23

14-08-2014, 07:23

|

#82

|

|

Registered User

Join Date: May 2011

Location: San Diego CA

Boat: Liberty 458

Posts: 2,205

|

Re: To Solder or Not.. That is the Question

As an engineer I'd stress that proper support in dynamic loadings is crucial to avoid placing unnecessary loads on a soldered joint. The fact the joint is less flexible than the wire is not an issue if supported correctly.

Sent from my GT-I9300 using Cruisers Sailing Forum mobile app

|

|

|

14-08-2014, 07:28

14-08-2014, 07:28

|

#83

|

|

Registered User

Join Date: May 2011

Location: San Diego CA

Boat: Liberty 458

Posts: 2,205

|

Re: To Solder or Not.. That is the Question

A soldered joint can have an optimum surface area whereas a crimped joint can't. This way high current joints like battery connections avoid high heat loading.

There is a time and place for crimps as well as for solder.

Sent from my GT-I9300 using Cruisers Sailing Forum mobile app

|

|

|

14-08-2014, 08:45

14-08-2014, 08:45

|

#84

|

|

Registered User

Join Date: Apr 2014

Location: Chicago

Boat: Alden auxiliary ketch 48'

Posts: 950

|

Re: To Solder or Not.. That is the Question

and a bonus question... Do you use tinned wire?

(I really want to know - so I read every post)

I personally have a Europeans view on tinned wire !!!

(OK, I'm of European ancestry but haven't a clue as to what that means)

tin is less conductive than copper - no need for tin

(now we're getting somewhere but it doesn't refer to the wire)

Every technical question on CF is answered in the first 5 posts.

(not this time, Ex-Calif  )

Since I am about to embark on the completion of my insanity project I will shortly need to buy a whole lot of wire for my boat. Do I need tinned wire, as the OP originally asked? From one post it looks like it actually interferes with conductivity. It's supposed to facilitate soldering but since I won't be soldering, will it interfere with crimping/conductivity? Is tinned wire an ABYC requirement? )

Since I am about to embark on the completion of my insanity project I will shortly need to buy a whole lot of wire for my boat. Do I need tinned wire, as the OP originally asked? From one post it looks like it actually interferes with conductivity. It's supposed to facilitate soldering but since I won't be soldering, will it interfere with crimping/conductivity? Is tinned wire an ABYC requirement?

__________________

Outside of a dog, a book is a man's best friend.

Inside of a dog, it's too dark to read.

|

|

|

14-08-2014, 09:10

14-08-2014, 09:10

|

#85

|

|

Nearly an old salt

Join Date: Jun 2009

Location: Lefkas Marina ,Greece

Boat: Bavaria 36

Posts: 22,801

|

Re: To Solder or Not.. That is the Question

Quote:

Originally Posted by leftbrainstuff

A soldered joint can have an optimum surface area whereas a crimped joint can't. This way high current joints like battery connections avoid high heat loading.

There is a time and place for crimps as well as for solder.

Sent from my GT-I9300 using Cruisers Sailing Forum mobile app |

Battery connections are best properly crimped with the appropriate tools.

Solder does not guarantee optimum surface. most amateurs cant solder properly or have inadequate tools and processes.

dave

__________________

Interested in smart boat technology, networking and all things tech Interested in smart boat technology, networking and all things tech

|

|

|

14-08-2014, 09:12

14-08-2014, 09:12

|

#86

|

|

Nearly an old salt

Join Date: Jun 2009

Location: Lefkas Marina ,Greece

Boat: Bavaria 36

Posts: 22,801

|

Re: To Solder or Not.. That is the Question

Quote:

Originally Posted by crazyoldboatguy

and a bonus question... Do you use tinned wire?

(I really want to know - so I read every post)

I personally have a Europeans view on tinned wire !!!

(OK, I'm of European ancestry but haven't a clue as to what that means)

tin is less conductive than copper - no need for tin

(now we're getting somewhere but it doesn't refer to the wire)

Every technical question on CF is answered in the first 5 posts.

(not this time, Ex-Calif  )

Since I am about to embark on the completion of my insanity project I will shortly need to buy a whole lot of wire for my boat. Do I need tinned wire, as the OP originally asked? From one post it looks like it actually interferes with conductivity. It's supposed to facilitate soldering but since I won't be soldering, will it interfere with crimping/conductivity? Is tinned wire an ABYC requirement? )

Since I am about to embark on the completion of my insanity project I will shortly need to buy a whole lot of wire for my boat. Do I need tinned wire, as the OP originally asked? From one post it looks like it actually interferes with conductivity. It's supposed to facilitate soldering but since I won't be soldering, will it interfere with crimping/conductivity? Is tinned wire an ABYC requirement?

|

Given the small enough differential between tinned and untinned and given your labour if free. Id use tinned wire. I would buy it from specialist electrical cable distributors rather then any " marine" brand

dave

__________________

Interested in smart boat technology, networking and all things tech Interested in smart boat technology, networking and all things tech

|

|

|

14-08-2014, 09:19

14-08-2014, 09:19

|

#87

|

|

Registered User

Join Date: Jul 2010

Location: East Tennessee

Boat: 1989 50 ft Roberts

Posts: 859

|

Re: To Solder or Not.. That is the Question

"Is tinned wire an ABYC requirement?" "...,.should be used" is what ABYC says about tinned wire.

|

|

|

14-08-2014, 09:22

14-08-2014, 09:22

|

#88

|

|

Senior Cruiser

Join Date: Mar 2003

Location: Thunder Bay, Ontario - 48-29N x 89-20W

Boat: (Cruiser Living On Dirt)

Posts: 49,331

|

Re: To Solder or Not.. That is the Question

Fresh, new, bare copper conductor works fine; but Tinning of individual wire strands in electrical conductors greatly reduces oxidation (corrosion), improves solderability, and improves electrical properties at high frequencies.

__________________

Gord May

"If you didn't have the time or money to do it right in the first place, when will you get the time/$ to fix it?"

|

|

|

14-08-2014, 09:27

14-08-2014, 09:27

|

#89

|

|

Registered User

Join Date: Apr 2014

Location: Chicago

Boat: Alden auxiliary ketch 48'

Posts: 950

|

Re: To Solder or Not.. That is the Question

Yeah, but what is the European view?

Thanks for the replies. It seems odd that folks are saying that non-tinned wire makes soldering more difficult when most folks do NOT recommend soldering. But the oxidation issue is clearer. As a fresh water sailor, I don't often see the problems that salt water sailors do but all the work on my vessel is done assuming a salt water environment. I never know when the transporter beam will take me to my south pacific paradise.

__________________

Outside of a dog, a book is a man's best friend.

Inside of a dog, it's too dark to read.

|

|

|

14-08-2014, 09:29

14-08-2014, 09:29

|

#90

|

|

Moderator

Join Date: Mar 2009

Location: Denmark (Winter), Helsinki (Summer); Cruising the Baltic Sea this year!

Boat: Cutter-Rigged Moody 54

Posts: 33,839

|

Re: To Solder or Not.. That is the Question

Quote:

Originally Posted by Wotname

My question was more intended to ask what do you think caused every PO joint to fail on your vessel. Was every joint subject to vibration? I'm thinking this would be unusual (but possible). I'm also thinking the PO may have used poor soldering practice and left flux behind thus causing accelerated corrosion which would also then lead to broken wires. Your first hand experience would be helpful to others to see exactly why the PO joints failed. |

The wire was very brittle from the wicked up solder near the terminals. A little vibration, a little deflection -- like when you pull a switch panel off, for example -- and the wire broke off near the terminal. I ended up redoing every one of them.

Not my first experience with this, either.

When I was restoring antique British sports cars with my Dad about a million years ago, one of my jobs was wiring. I had a $1.99 Western Auto crimper and a plastic pigeonhole box full of crap terminals. I bet I'm not the only person on here who has experience with these. I was a teenager and this was before Internet, and I had no idea what proper tools or terminals were. I was pretty good at soldering, so I thought it would be really cool and really top class to crimp the terminals, then solder them. So I would lovingly apply flux, heat up the terminals to just the right temp, and flow the solder into the terminal. It looked really nice and I thought I was doing first-class work. I really enjoyed soldering when I was a teenager.

Well, all my terminals failed quickly -- in the same way as the PO's terminals on my boat. We used to tell jokes about Lucas, the Prince of Darkness, and the bottles of genuine Lucas wire smoke, but to be honest, most of the electrical failures and even fires (!) were because of my misguided terminal technique. We often sold the cars we restored in order to buy new basket cases (it was an idiotic hobby, looking back on it), and one friend of my Dad's who bought an MGA I had rewired was quite irate when all the wiring failed after less than a month. So I stopped doing wiring and we had a friend of ours do it for us for barter -- my Dad painted in lacquer, beautifully (guess who got to rub it out, though  ). This friend of ours worked on aircraft and had a proper crimper, which I had never seen before. Buying one for myself was way out of my reach in those days, so that was the end of my career as an auto electrician

|

|

|

|

|

| Thread Tools |

Search this Thread |

|

|

|

| Display Modes |

Rate This Thread |

Linear Mode Linear Mode

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Advertise Here

Recent Discussions Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vendor Spotlight Vendor Spotlight |

|

|

|

|

|

|

|

|

|