|

|

03-06-2008, 07:00

03-06-2008, 07:00

|

#16

|

|

Moderator and Certifiable Refitter

Join Date: Jan 2008

Location: South of 43 S, Australia

Boat: C.L.O.D.

Posts: 20,400

|

Quote:

Originally Posted by Wotname

If it won't solder easily, if won't crimp very well.

|

Should have read "If it won't solder easily, it won't crimp very well" - sorry for any confusion.

__________________

All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find it was vanity: but the dreamers of the day are dangereous men, for they may act their dreams with open eyes, to make it possible. T.E. Lawrence

|

|

|

03-06-2008, 07:34

03-06-2008, 07:34

|

#17

|

|

Moderator and Certifiable Refitter

Join Date: Jan 2008

Location: South of 43 S, Australia

Boat: C.L.O.D.

Posts: 20,400

|

Waterproof splice and crimping

Charlie, I am not hijacking your thread but it is already drifting away from tinned v copper towards crimping and sealing so let me add some more info:

Waterproof wire splice/crimping - it is hard to beat these TYCO moistureproof splices http://www.aircraftmech.com/splicetool.html

Crimp tooling - For a high end quality job, the correct crimp tooling to use is the one made by the manufacturer of the crimp terminal i.e. if you are using an AMP PIDG terminal, use an AMP PIDG crimp tool etc.

__________________

All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find it was vanity: but the dreamers of the day are dangereous men, for they may act their dreams with open eyes, to make it possible. T.E. Lawrence

|

|

|

03-06-2008, 07:54

03-06-2008, 07:54

|

#18

|

|

Registered User

Join Date: Mar 2006

Location: Nevada City. CA

Boat: Sceptre 41

Posts: 3,857

|

My opinion is that tinned wire is better. I don't believe that this is in question. In all my connections I have used tinned wire. Being a contractor I can buy wire at wholesale prices so there is a big difference between the price of tinned vs. stranded wire. What I am wondering is whether or not it is worth replacing wire that seems to be in good shape with new wire. My boat is 23 years old and all the untinned wire that has been kept reasonable dry seems to be in good shape. I guess that speaks to the quality of stranded wire. If the boat had been wired in tinned wire I might get fifty years out of the wire. So where is the big advantage of tinned over untinned? I can see it in damp locations but even then I would think that with proper sealed connections the non tinned wire would last long enough. Not as long as tinned wire -- but long enough.

__________________

Fair Winds,

Charlie

Between us there was, as I have already said somewhere, the bond of the sea. Besides holding our hearts together through long periods of separation, it had the effect of making us tolerant of each other's yarns -- and even convictions. Heart of Darkness

Joseph Conrad

|

|

|

03-06-2008, 14:40

03-06-2008, 14:40

|

#19

|

|

Registered User

Join Date: Mar 2006

Location: Winnipeg

Boat: None at this time

Posts: 8,462

|

If the connections are solid and the wire/connections show no sign of heat under load or visual signs of corrosion then I would leave them alone. However if any circuit required repair I would replace the wire with tinned marine grade wire. That's my opinion.

|

|

|

03-06-2008, 15:59

03-06-2008, 15:59

|

#20

|

|

Senior Cruiser

Join Date: Sep 2003

Location: Minneapolis MN

Boat: Searunner 40 Trimaran, Siruis 22 mono, 16 foot MFG daysailor

Posts: 515

|

I think Acoustic makes a good point about the jacket material. The wire on my 26 year old tri is non tinned and in most places it is still in good shape. The exception is where the PO added some things using cheap lamp cord or zip cord (speaker wire). This stuff allows moisture to permeate through the jacket over time. It is amazing how often this junk gets used on board a boat. While no doubt tinned is better I don't think it is necessary except possibly in damp areas like the bilge or engine compartment. In my job in the high end corporate audio visual installation biz we use thousands of feet of high quality AWG wire with a PVC jacket from Beldon and West Penn. The last job we did filled the bed of a 3/4 ton pick-up to overflowing with the scrap and excess. I keep whatever I need in random lengths to 100 feet. So I plan on using this to rewire my boat, most of it 12-16 gauge. Anything larger I will need to buy. Along with heat shrink on the ends it will last as long as I need it to. Maybe tinned wire will last 50 years but with the advance of technology how many electrical systems will be hopelessly outdated after just 20 or 25?

__________________

Don't trust your dog to guard your lunch.

Patrick, age 9

|

|

|

03-06-2008, 16:38

03-06-2008, 16:38

|

#21

|

|

Moderator and Certifiable Refitter

Join Date: Jan 2008

Location: South of 43 S, Australia

Boat: C.L.O.D.

Posts: 20,400

|

Yes, I have to agree with Deep - if the copper wiring seems OK at this stage, don't replace it (unless you are doing a major refit anyway).

And as Steve and Acoustic has already mentioned, the quality of the insulating material becomes more important when considering copper wire.

__________________

All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find it was vanity: but the dreamers of the day are dangereous men, for they may act their dreams with open eyes, to make it possible. T.E. Lawrence

|

|

|

03-06-2008, 16:48

03-06-2008, 16:48

|

#22

|

|

Guest

Posts: n/a

|

So we all agree that tinned wire is "best", the difference is if it is worth the cost.

What people seem to be missing is that while tinning is an optional addition to "boat wire" there are other specifications that are NOT optional.

Three key things that you should be SURE your wire has:

FIrst, it should be fine strand so it is flexible and doesn't work harden. This is not an issue in 99% of the wiring runs on a boat, but that 1% just might get you.

The insulation should have a minimum of 105C temperature rating dry and 75C wet. If it does not, you must de-rate its ampacity and fuse it lower than than the normal references suggest or you risk melting the insulation.

Finally the insulation should be resistant to water, oil and fuel.

If the "contractor stranded wire" or AV cable doesn't have these specifications printed on the insulation, how do you know they meet it? I be surprised the AV cable that Steve want to use because it is free meets those specs no matter how expensive it is.

Once you have seen a boat fire started by a shortcut electrical installation you tend to get religion.

Finally, I don't know about anybody else, but there are very few places one my boat I can assure you will be dry always and forever. Even absent leaks, in some climates condensation can get into the oddest places on a liveaboard boat. I wire my boat assuming any part might be at least damp. Just seems smart.

|

|

|

|

03-06-2008, 18:11

03-06-2008, 18:11

|

#23

|

|

Marine Service Provider

Join Date: Jan 2007

Location: Maine

Boat: CS-36T - Cupecoy

Posts: 3,197

|

For those...

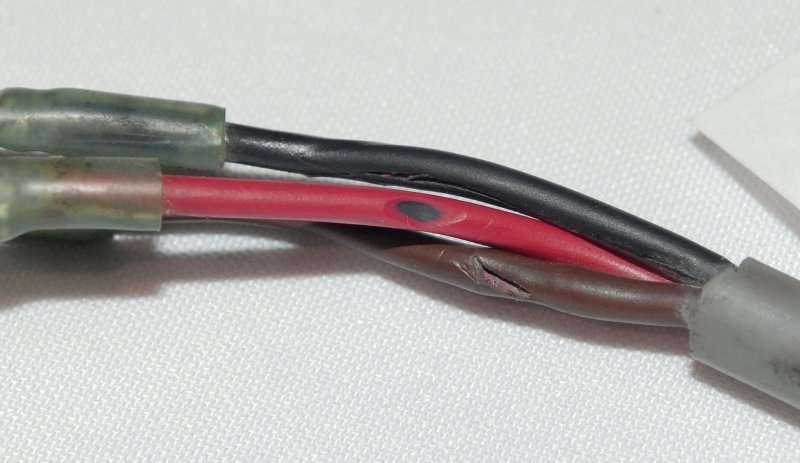

For those who under estimate the importance of good installation technique and who are doubters of vibration I bring you the following photo.

A friend installed this bilge pump wiring less than a year prior to me ripping it out and starting over.

In less than 3" of wire I found three MAJOR problems.

#1 Both the black and brown wires were nicked to the core during the stripping of the outer jacket of the wire.

#2 The red wire, in less than a year, was already worn, from vibration, to the point that the insulation was less than the thickness of a human hair from the positive wires! Less than a YEAR and this was in the bilge of a fin keeler and nowhere near the engine!! LESS THAN A YEAR!!!! Vibration is REAL on boats..!

#3 When he shrunk the heat shrink connectors he did not look for clear and consistent color and proper uniform coloration and melt of the adhesive. There are areas of discoloration, or voids/air pockets, that were allowing water right into the crimp because he was sloppy with his heat shrinking.

Again, all this in 3" of ONE wire on a boat!!

|

|

|

03-06-2008, 19:23

03-06-2008, 19:23

|

#24

|

|

Registered User

Join Date: Mar 2006

Location: Winnipeg

Boat: None at this time

Posts: 8,462

|

Quote:

|

Once you have seen a boat fire started by a shortcut electrical installation you tend to get religion.

|

Amen Brother! Most boat fires are started as the result of an electrical fault. Period. Why would anyone take a chance on doing a less than excellent job with the best possible materials and tools.

In Vancouver, tied to the pier behind the Coast Guard station on False Creek, there was a hull that was plainly visible at low tide. Had been a nice power boat, burned to the waterline. I used to see it every time I took my boat out. It was a good reminder to me to do things right as I can let myself get in a rush and just want to get it done. As Gord May often say, If you don't have the time/money to do things right the first time, when will you have the time/money to do it right?

|

|

|

03-06-2008, 19:33

03-06-2008, 19:33

|

#25

|

|

Registered User

Join Date: Mar 2006

Location: Nevada City. CA

Boat: Sceptre 41

Posts: 3,857

|

Quote:

Originally Posted by GreatKetch

So we all agree that tinned wire is "best", the difference is if it is worth the cost.

What people seem to be missing is that while tinning is an optional addition to "boat wire" there are other specifications that are NOT optional.

Three key things that you should be SURE your wire has:

FIrst, it should be fine strand so it is flexible and doesn't work harden. This is not an issue in 99% of the wiring runs on a boat, but that 1% just might get you.

The insulation should have a minimum of 105C temperature rating dry and 75C wet. If it does not, you must de-rate its ampacity and fuse it lower than than the normal references suggest or you risk melting the insulation.

Finally the insulation should be resistant to water, oil and fuel.

If the "contractor stranded wire" or AV cable doesn't have these specifications printed on the insulation, how do you know they meet it? I be surprised the AV cable that Steve want to use because it is free meets those specs no matter how expensive it is.

Once you have seen a boat fire started by a shortcut electrical installation you tend to get religion.

Finally, I don't know about anybody else, but there are very few places one my boat I can assure you will be dry always and forever. Even absent leaks, in some climates condensation can get into the oddest places on a liveaboard boat. I wire my boat assuming any part might be at least damp. Just seems smart. |

GK:

You sure are pedantic on tinned wire.

I don't know about AV wire but I know that contractor grade wire is stamped on its insulation as to the qualities it has.

Fires can be caused by tinned or untinned wire their is no correlation between fire and whether there is tin on the wire. It has to do directly with load and/or installation.

When I have a leak in my boat I fix it. Some areas are more prone to being wet than others. But if the insualtion is rated for water etc. It comes down to your splices to see if the wiring is going to hold up.

Most of the people who have boats on this forum have older boats. Boats that were produced before tinned wire became avaialble I would venture to guess. Mine is not tinned. Anytime I see a problem I replace the wire. I use tinned wire but after reading the article in PS I wanted to see what other people thought about the importance of using tinned wire. It seems that their is a wide range of opinions.

__________________

Fair Winds,

Charlie

Between us there was, as I have already said somewhere, the bond of the sea. Besides holding our hearts together through long periods of separation, it had the effect of making us tolerant of each other's yarns -- and even convictions. Heart of Darkness

Joseph Conrad

|

|

|

04-06-2008, 00:47

04-06-2008, 00:47

|

#26

|

|

Senior Cruiser

Join Date: Dec 2003

Location: Marlborough Sounds. New Zealand

Boat: Hartley Tahitian 45ft. Leisure Lady

Posts: 8,038

|

Quote:

|

You should always use highly flexible wire on a boat. I don't understand the rational Alan has for doing otherwise.

|

I didn't say not too. I am not sure why you think I did. I do agree with your reasoning of vibration and movement, however, I also don't see the need for very very fine highly flexible. Automotive cable is plenty flexible enough. Battery cable is often made with very fine wire strands because it is primarily made for welding cable which needs to be very flexible for it's size.

Warning, those crimp joiners that heat shrink down on the cable shown above, are not waterproof. If you want them waterproof, a little hot melt glue in the sleeve while you heatshrink it down will solve that. But you need to ensure the proper crimp tool is used, as the cheapies will damage the sleeve and once again it is not waterproof.

__________________

Wheels

For God so loved the world..........He didn't send a committee.

|

|

|

04-06-2008, 12:35

04-06-2008, 12:35

|

#27

|

|

Guest

Posts: n/a

|

Quote:

Originally Posted by Charlie

GK:

You sure are pedantic on tinned wire.

I don't know about AV wire but I know that contractor grade wire is stamped on its insulation as to the qualities it has.

Fires can be caused by tinned or untinned wire their is no correlation between fire and whether there is tin on the wire. It has to do directly with load and/or installation.

|

Read, what I said...

What I tried to get across was that tinned wire is a nice option. What I want to discourge people from doing is using whatever is CHEAP instead of real boat spec wire.

I TRIED to point out that tinning is just an add on, and that boat spec wire has other MORE IMPORTANT properties.

|

|

|

|

04-06-2008, 13:26

04-06-2008, 13:26

|

#28

|

|

Guest

Posts: n/a

|

Quote:

Originally Posted by Alan Wheeler

Not really sure why you want fine strands. The finer strands allow for a very flexible cable. You don't want too stiff a cable, but you don't need a flex either.

|

Sorry if I missed what you said earlier. I thought you had implied that wire that was too flexible was undesirerable. A closer reading indicates you were clear, and my reading of it was at best imprecise :P

Since I don't wire cars, I am not at all sure what "automotive wire" is and what insulation and stranding specifications are used.

When I talk about "flexible wire" there are two specs that are relevant to use on boats. "Type 2" which is 16 strand for 18 AWG, and 19 strand for sizes through 8 AWG. This is recommended for "general wiring".

For wire that will be subject to regular flexing, there is "Type 3" which has 26 strands for 16 AWG, 41 for 14 AWG, 65 for 12 AWG, etc....

|

|

|

|

04-06-2008, 13:30

04-06-2008, 13:30

|

#29

|

|

Registered User

Join Date: Mar 2006

Location: Winnipeg

Boat: None at this time

Posts: 8,462

|

Also, just a reminder as was mentioned earlier in this thread. SAE wire is smaller diameter than ABYC spec'd wire.

|

|

|

04-06-2008, 21:23

04-06-2008, 21:23

|

#30

|

|

Senior Cruiser

Join Date: Sep 2003

Location: Minneapolis MN

Boat: Searunner 40 Trimaran, Siruis 22 mono, 16 foot MFG daysailor

Posts: 515

|

Quote:

Originally Posted by GreatKetch

If the "contractor stranded wire" or AV cable doesn't have these specifications printed on the insulation, how do you know they meet it? I be surprised the AV cable that Steve want to use because it is free meets those specs no matter how expensive it is.

|

Much of the wire we use is rated to be used in a plenum air space in commercial buildings and is considered the top of the line in fire and heat resistant wire. The jacket is actually Teflon FEP (fluorinated ethylene propylene) not PVC as I misstated earlier. PVC is used in the non-plenum wire that we use in conduit or non plenum ceilings. It is my understanding that PVC cannot meet plenum standards. What is the jacket on marine wire? PVC, maybe vinyl? Anyway, I have no reservations at using the plenum rated wire. Many outside the low voltage industry may not be familiar with this type of wire. I am sure it's overkill but it is free so I use it.

__________________

Don't trust your dog to guard your lunch.

Patrick, age 9

|

|

|

|

|

| Thread Tools |

Search this Thread |

|

|

|

| Display Modes |

Rate This Thread |

Linear Mode Linear Mode

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

Similar Threads

Similar Threads

|

| Thread |

Thread Starter |

Forum |

Replies |

Last Post |

|

wire chart ?

|

cooper |

Electrical: Batteries, Generators & Solar |

30 |

22-03-2008 14:36 |

|

Tinned Butter

|

NoTies |

Cooking and Provisioning: Food & Drink |

6 |

14-03-2008 11:30 |

|

Re-wiring: Tinned or not. Also cabin lights...

|

Weyalan |

Electrical: Batteries, Generators & Solar |

23 |

02-12-2006 11:29 |

|

Wire

|

irwinsailor |

Construction, Maintenance & Refit |

35 |

30-03-2006 05:10 |

|

hot wire

|

tauras |

Health, Safety & Related Gear |

17 |

01-08-2004 23:22 |

|

Advertise Here

Recent Discussions Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vendor Spotlight Vendor Spotlight |

|

|

|

|

|

|

|

|

|