|

|

30-12-2013, 13:21

30-12-2013, 13:21

|

#1

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Load Testing Results

I am starting a series of tests.

Today I ran what I had expected to be some simple calibration tests to see how repeatable the results were.

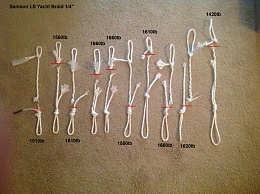

I made up 10 samples, Samson LS Yacht braid 1/4", with a bowline on one end and a figure 8 loop on the other.

I had expected them all to break at the bowline, at about 50% of line strength, in a relatively tight grouping of breaking loads.

5 of the samples broke at the bowline at 83% of the rated line strength, with a 5% standard deviation

And 5 broke at the figure 8 at 84% of the line strength, with 3% standard deviation

It is really too small a sample for any sort of statistical calculation, but the test results were relatively tightly grouped, so I draw two conclusions (a) the breaking loads were higher than I expected, ( b ) there was no significant difference between the bowline and figure 8 in this line

|

|

|

30-12-2013, 13:24

30-12-2013, 13:24

|

#2

|

|

Registered User

Join Date: Jun 2009

Location: In transit ( Texas to wherever the wind blows us)

Boat: Pacific Seacraft a Crealock 34

Posts: 4,115

|

Re: load testing results

Very cool, very very cool. Thanks for doing this and sharing your results.

|

|

|

30-12-2013, 13:25

30-12-2013, 13:25

|

#3

|

|

Registered User

Join Date: Jun 2010

Location: Now limited to seasonal NE sailing

Boat: PT-11

Posts: 1,541

|

Re: load testing results

Interesting. What is the test equipment setup?

|

|

|

30-12-2013, 13:37

30-12-2013, 13:37

|

#4

|

|

Registered User

Join Date: Mar 2010

Boat: Prout 46

Posts: 166

|

Re: load testing results

What did your control (no knot) line break at?

|

|

|

30-12-2013, 13:59

30-12-2013, 13:59

|

#5

|

|

Writing Full-Time Since 2014

Join Date: Nov 2008

Location: Deale, MD

Boat: PDQ Altair, 32/34

Posts: 9,601

|

Re: load testing results

Oooooo. Data!

I can't say I'm surprised. In some lines a bowline is very strong. Sometimes, in climbing rope drop testing, the line breaks away from the knot (a figure-8 knot is purposefully included in the test, since it represents part of rope function). Was it possible to untie the bowlines after loading? I always could. Figure-8s became impervious above about 20% load.

In my experience, except for overload situations, lines most often go due to chafe. There have been 2 common exceptions:

- Jib clews. I have had several jib sheets fail due to line fatigue at the entrance to the knot (figure-8 in clew pendant and twice at larks head). It was NOT weakening due to the knot--the knot did not fail inside where it would normally fail--but rather the result of repeated hard flexing during flogging. One of these was Kevlar; the core was gone but the horrifically sunburned cover still held!

- Anchor lines on floating wastewater plant mixers. Same problem; frequent flexing, concentrated at the knot. In this case threading a hose over the line solved the problem (there were also cutting issues and this cured both).

- Lazy jacks. Failed at the knot entrance, where they are bent sharply over pad eyes or something similar. Lots of UV damage (there's no UV inside a knot). The boom end always fails first, even though the top (mast) attachment certainly feels more strain and gets more UV (not covered). In this case it is low speed flexing and UV that combine, I think; the flexing cracks the weakened fibers, the inside of the knot does not flex.

Splicing does better in these examples, not be cause it is stronger, but because it can function as a natural strain relief. This difference is relevant to any flexing application. My theory, anyway.

Other than snubber failures, which are generally overload failures, what knot failures have you experienced, and did they break inside the knot (knot strength) or at the entrance to the knot (flexing)? I guess I'm wondering if knots fail in the field in the same ways that they fail on the test stand. I think often they do not.

This brings up a whole new sort of fatigue testing; sharp flexing under variable load. Not even rope manufactures test it this way.

---

If you used the spliced strength as a control (or your own spliced sample) there is ~ 10% offset in the data; knot efficiencies are by comparison to splice strength.

|

|

|

30-12-2013, 14:39

30-12-2013, 14:39

|

#6

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: load testing results

The 'rated strength' is 'average with two splices' according to samson. I can and will (a bit later) replicate that test to check the rated strengths because I want them comparable between mfgs.

None of those lines broke in the middle ( in the above or below test). They all broke near the knot exits. On some of the breaks it was 'clean' and on others it was progressive, with a core tail that broke last.

Second test:

Samson XLS yacht braid 1/4"

Again 50% broke with the bowline at 83% rated strength, 3% standard deviation

And 50% broke at the figure 8 with 79% rated strength, 2% standard deviation

Conclusions . . results similar to test 1 but a bit tighter grouped. Bowline = figure 8, Dacron double braid with both knots about 80% of rated average splice strength.

|

|

|

30-12-2013, 14:47

30-12-2013, 14:47

|

#7

|

|

Moderator Emeritus

Join Date: Jan 2012

Location: Northern NSW.Australia

Boat: Sunmaid 20, John Welsford Navigator

Posts: 9,549

|

Re: load testing results

Practical Boat Owner magazine in the UK just did a similar thing in the November issue. Not sure if you can see it online anywhere.

Coops.

__________________

When somebody told me that I was delusional, I almost fell off of my unicorn.

|

|

|

30-12-2013, 14:54

30-12-2013, 14:54

|

#8

|

|

Registered User

Join Date: Aug 2006

Location: Skagit City, WA

Posts: 25,514

|

Re: load testing results

Isnt a bowline supposed to be about 80%? or has that changed?

__________________

"I spent most of my money on Booze, Broads and Boats. The rest I wasted" - Elmore Leonard

|

|

|

30-12-2013, 14:58

30-12-2013, 14:58

|

#9

|

|

Moderator Emeritus

Join Date: Jan 2012

Location: Northern NSW.Australia

Boat: Sunmaid 20, John Welsford Navigator

Posts: 9,549

|

Re: load testing results

According to PBO. Polyester braid on braid 67%, polyester three strand 64% and nylon multiplait 58%. All for bowline, all as a percentage of manufacturer's specified break load.

They also tested round turn and two half hitches, clove hitch, fisherman's bend and soft eye splice in the same three ropes. Plus, short splice,end to end splice, bowline to bowline,fisherman's slip knot, reef knot,and a couple of anchor line splices and knots.

Coops.

__________________

When somebody told me that I was delusional, I almost fell off of my unicorn.

|

|

|

30-12-2013, 15:03

30-12-2013, 15:03

|

#10

|

|

Writing Full-Time Since 2014

Join Date: Nov 2008

Location: Deale, MD

Boat: PDQ Altair, 32/34

Posts: 9,601

|

Re: load testing results

Quote:

Originally Posted by Cheechako

Isnt a bowline supposed to be about 80%? or has that changed?

|

Google "knot strength" and you will learn that it depends on...

- material

- construction

- size

- age

- wet/dry

- manufacture (ropes that should be the same but but test different).

"Supposed to" has flexible meaning in this context. Sort of like principles my mother believes are universal.

I wouldn't quote authorities; most have summarized scatter data and presented averages. Unless you know EXACTLY what they tested (like Starzinger) such numbers are generally useless. I'm am very anxious to see what sort of scatter the OP finds as he works his way through the variables. So far, the impression is that the data is reasonably repeatable for any given line. That is the starting point.

---------

Unless you have big drums to wrap the line around, the 2 splice method is best; it prevents the line from breaking on the hook, since the eye legs only carry ~ 50% each (depending on the construction, the distribution is actually a small bit different from that).

|

|

|

30-12-2013, 15:07

30-12-2013, 15:07

|

#11

|

|

Marine Service Provider

Join Date: Jan 2007

Location: Maine

Boat: CS-36T - Cupecoy

Posts: 3,197

|

Re: load testing results

Evans,

During my early days pull testing crimp terminals I kept breaking the wire at a bowline before the crimp failed. I switched to a buntline and the problems went away. I was not totally surprised the bowline impacted even finely stranded copper but it did..

|

|

|

30-12-2013, 15:54

30-12-2013, 15:54

|

#12

|

|

Marine Service Provider

Join Date: May 2012

Location: New Orleans

Boat: We have a problem... A serious addiction issue.

Posts: 3,974

|

Re: load testing results

One of the important things about line strength is that manufacturers typically spec line a MBL (minimum breaking strength). So any particular piece of line is often substantially stronger than the MBL as given. You may want to see if you can acquire the average or median breaking strength from the manufacturers test.

__________________

Greg

- If animals weren't meant to be eaten then they wouldn't be made of food.

|

|

|

30-12-2013, 16:50

30-12-2013, 16:50

|

#13

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: load testing results

Quote:

Originally Posted by thinwater

So far, the impression is that the data is reasonably repeatable for any given line. That is the starting point.

|

Yes, you understand exactly what I am trying to do.

I really should be doing 30 pulls in each test. That would allow me to do proper T and Z tests, but at 3' of line per pull that goes thru a lot of line quickly. So, I am short cutting a little when the results look low stdev.

|

|

|

30-12-2013, 16:50

30-12-2013, 16:50

|

#14

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: load testing results

Stupid spread sheet error in test 2 (test 1 still correct).

Correct test 2 results are a little lower, but still higher than expected:

50% broke with the bowline at 71% rated strength, 3% standard deviation

50% broke at the figure 8 with 69% rated strength, 2% standard deviation

I just did the double end splice test (5 with each line) to check rated strength. They are very close (statistically equal to) to Samson's ratings.

XLS 98% of rated with 1% Stdev

And

LS 99% with 4% Stdev.

These were sewn splices - I did that because they are more repeatable (at least for me) than class 1 DB splices. All broke in the middle of the line, or near the first stitch (nearest the middle of the line).

I have some nylon line to test but I need to increase (about double) my hydraulic travel. Right now I can just handle the stretch of Dacron, and I will be perfectly fine with dyneema, but nylon will stretch and not break with my current travel. I have a longer ram ordered. I have it in my plan to test less dressed knots, including not pulled tight bowlines . . .but right now I am trying for the highest repeat-ability possible.

Not yet sure what to make of the higher than expected bowline results in dacron double braid. It is still early days in testing.

|

|

|

31-12-2013, 06:19

31-12-2013, 06:19

|

#15

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: load testing results

I plan to look at the bunt line hitch today, but because I had some splices left over from yesterday I did some quick bends:

Samson LS (dacron double braid)

Sheet Bend: Slipped at 51% of rated strength

Double Sheet Bend: broke at 65%

Double Fisherman: Broke at 74%

Samson XLS (dacron double braid)

Sheet Bend: Slipped at 50% of rated strength

Double Sheet Bend: broke at 65%

Double Fisherman: Broke at 65%

Since the sheet bends slipped in both lines I think it will be worth looking at the other 'quick' bends like the ashley and zeppelin.

I have various dyneema on the way, but it has not arrived yet.

|

|

|

|

|

| Thread Tools |

Search this Thread |

|

|

|

| Display Modes |

Rate This Thread |

Linear Mode Linear Mode

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Advertise Here

Recent Discussions Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vendor Spotlight Vendor Spotlight |

|

|

|

|

|

|

|

|

|