|

|

20-11-2015, 06:19

20-11-2015, 06:19

|

#16

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: Jack line stiching

oh, yea, machine bar tacks . . . . you need a specialize machine to make completely correct bar tacks. BUT if you have a machine with adjustable zigzag (like my sailrite) you can get a close approximation by turning the zigzag stitch length way up and the stitch spacing way down. If you do this neatly the strength is the same (with my testing tolerances) of 'proper' bar tacks.

And proper even stitch tension and neatness does count here in strength.

|

|

|

20-11-2015, 08:02

20-11-2015, 08:02

|

#17

|

|

Writing Full-Time Since 2014

Join Date: Nov 2008

Location: Deale, MD

Boat: PDQ Altair, 32/34

Posts: 9,601

|

Re: Jack line stiching

Quote:

Originally Posted by Dennis.G

I think double action hooks are required by some offshore racing rules. |

They are required by ISO (in the tether standard).

|

|

|

20-11-2015, 09:10

20-11-2015, 09:10

|

#18

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: Jack line stiching

Quote:

Originally Posted by thinwater

They are required by ISO (in the tether standard).

|

well, sort of . . . the ISO text reads: "All hooks provided shall be of a self-closing type, with an opening large enough to accept, and fully close on, a cylinder of diameter 12.5mm. There shall be no tendency for the hook to open by any action, as tested in 5.4, other than by deliberate release, expect when a clear a permanent warning label as specified in 5.4 and 6g indicates that an attachment bracket is fitted to the craft."

The 5.4 specified test is basically twisting the hook on a rod, eye bolt and U bolt. If it will release while being twisted it fails.

The bottom line is that quite a wide range of hooks can pass this test - but most very simple non-locking carabiner designs will fail. And if you don't like any of the hooks which pass, you can stick warning labels all over your boat and still comply.

PS - pet peeve of mine that the sport is using these private standards, which are outrageously priced if an owner wants to read and understand them. I think that sucks.

|

|

|

20-11-2015, 14:28

20-11-2015, 14:28

|

#19

|

|

Moderator and Certifiable Refitter

Join Date: Jan 2008

Location: South of 43 S, Australia

Boat: C.L.O.D.

Posts: 20,401

|

Re: Jack line stiching

Quote:

Originally Posted by estarzinger

The direct answer to the question is bar tacks, with as heavy thread as you or your sewing machine can handle.

" the first 2 or 3 stitches at end of a longitudinal run carries the load."

It is actually the stitches in the first 2" or so that carry the load. So you essentially want to pack as much bar tacking into that area as you can. But it also makes sense to keep stitching for about 6", so that if the first 2" do break you have 3 more 'zipper opportunities' to absorb the shock load and catch it before the whole thing lets go.

…... |

I'm curious now…

When you say the first 2" carry the load, are you referring to transverse rows of bar tacking or the first 2" on longitudinal straight sticking.

__________________

All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find it was vanity: but the dreamers of the day are dangereous men, for they may act their dreams with open eyes, to make it possible. T.E. Lawrence

|

|

|

20-11-2015, 17:23

20-11-2015, 17:23

|

#20

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: Jack line stiching

Quote:

Originally Posted by Wotname

I'm curious now…

When you say the first 2" carry the load, are you referring to transverse rows of bar tacking or the first 2" on longitudinal straight sticking.

|

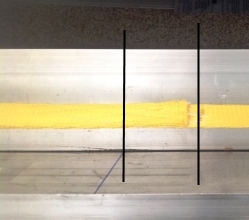

I can't find a great photo - I took most of them after the break rather than during. But here is a low rez one of loop under load. Most of the load is being carried by the stitches between the two black lines. This is true no matter what stitching pattern is used. It is less severe with lower stretch webbing (eg dyneema webbing spreads the load over a longer area).

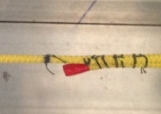

here is another low rez picture of a sewn rope loop under load. When not under load all these stitches were perpendicular to the rope. You can see the stitches are angled (stretched under load) at the start of the sewing, but perpendicular (not loaded) at the other end of the sewing.

I should not that, despite the fact they look similar, the load pattern on an 'end loop' is different than on an 'end to end lap joint'. And this has implications on the optimal stitching pattern. Also the elasticity of the webbing has implications - eg Nylon different than dyneema (low stretch spreads the load more evenly to more stitching).

|

|

|

20-11-2015, 17:59

20-11-2015, 17:59

|

#21

|

|

Registered User

Join Date: Feb 2013

Location: Oregon

Boat: Seafarer36c

Posts: 5,563

|

Re: Jack line stiching

I realize without pictures it's of little value, but I tested my stitching today in a hydraulic press. I used 1/2" drive extensions for the ends. There is no pressure gauge so I don't know what was what either. I can say that it took a good amount of pressure before things started to fail. You could hear the first stitch fail then the others. There was a loop on both ends so I had different stitch patterns on each. The nice looking one held. This was 4500 lb webbing.

Interesting for sure, I even saw the good quality 1/2 drive extensions bend.

|

|

|

20-11-2015, 18:39

20-11-2015, 18:39

|

#22

|

|

Writing Full-Time Since 2014

Join Date: Nov 2008

Location: Deale, MD

Boat: PDQ Altair, 32/34

Posts: 9,601

|

Re: Jack line stiching

Quote:

Originally Posted by estarzinger

PS - pet peeve of mine that the sport is using these private standards, which are outrageously priced if an owner wants to read and understand them. I think that sucks.

|

Yes, exactly what you said. about hooks. Another practical problem with non-locking carabiners is that they can clip onto another line as they slide by; imagine you hooked a jib sheet. It can happen.

As for standards, I belong to ASTM, which is similar to ISO. The standards are for the members, by the members, and the association is supported primarily by the sale of standards. Antifreeze, for example, is governed by ASTM D3306, but you have to buy the standard. Even more troubling are mechanical, electrical, and even fire codes that are accessible only through purchase. As you point out, the situation is global (ISO). Then our governments incorporate many of these by reference; the law can be downloaded, but not the specifics, which are buried in the standards.

In this age of information this seems so very strange. One solution would be to have the government write the standards... which would be FAR worse, I think. But still, it is a rotten situation.

|

|

|

20-11-2015, 18:44

20-11-2015, 18:44

|

#23

|

|

Writing Full-Time Since 2014

Join Date: Nov 2008

Location: Deale, MD

Boat: PDQ Altair, 32/34

Posts: 9,601

|

Re: Jack line stiching

Quote:

Originally Posted by Wotname

I'm curious now…

When you say the first 2" carry the load, are you referring to transverse rows of bar tacking or the first 2" on longitudinal straight sticking.

|

I found Starzinger's response correct but a little confusing.

I think the short answer is the bar tacks carry the load and the longitudinal stitching does little, which is why climbing slings are only bar tacked.

To understand what is going on, imagine the difference between sewing and elastic waist band (only the first row of stitching does anything at all) and bolting a chain plate (all bolts share equally). A great deal depends on whether you are stitching nylon (very difficult to get right) or Dyneema (easy, just needs lost of stitches).

|

|

|

21-11-2015, 00:36

21-11-2015, 00:36

|

#24

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: Jack line stiching

Quote:

Originally Posted by Guy

I realize without pictures it's of little value, but I tested my stitching today in a hydraulic press. I used 1/2" drive extensions for the ends. There is no pressure gauge so I don't know what was what either. I can say that it took a good amount of pressure before things started to fail. You could hear the first stitch fail then the others. There was a loop on both ends so I had different stitch patterns on each. The nice looking one held. This was 4500 lb webbing.

Interesting for sure, I even saw the good quality 1/2 drive extensions bend.

|

Nice initiative. Can I suggest you test break a piece with a water knot loop on one end and your best sewn loop on the other. That would give you a result vs a known benchmark (we have test results fir the water knot). And take some good photos as it stretches and breaks.

4500lbs is a relatively high load - will break quite a few blocks, higher than you typically see in storm force anchoring.

|

|

|

21-11-2015, 01:58

21-11-2015, 01:58

|

#25

|

|

Registered User

Join Date: Jun 2014

Location: Up the mast, looking for clean wind.

Boat: Currently Shopping, & Heavily in LUST!

Posts: 5,629

|

Re: Jack line stiching

Anyone know who gave the official nod to those double action safety hooks?

I ask as I've been able to permanently deform (& open) a good number of them, using only hand pressure, applied from the side. Which turned me off from them completely.

Especially as it seems that many of them are only made from stamped/pressed, thin, sheet metal (with eased edges).

Of course, it's obvious that some of the sailing "safety rules", were mandated by a quorum of idiots... but that's another story entirely.

And, my apoligies for the thread drift, in an otherwise great thread.

__________________

The Uncommon Thing, The Hard Thing, The Important Thing (in Life): Making Promises to Yourself, And Keeping Them.

|

|

|

21-11-2015, 11:58

21-11-2015, 11:58

|

#26

|

|

Registered User

Join Date: Feb 2013

Location: Oregon

Boat: Seafarer36c

Posts: 5,563

|

Re: Jack line stiching

Quote:

Originally Posted by estarzinger

Nice initiative. Can I suggest you test break a piece with a water knot loop on one end and your best sewn loop on the other. That would give you a result vs a known benchmark (we have test results fir the water knot). And take some good photos as it stretches and breaks.

4500lbs is a relatively high load - will break quite a few blocks, higher than you typically see in storm force anchoring. |

The water knot won. The stitching failed again. This may be 4500lb test webbing but I think we are way over that. The thread seems to be failing most on the bobbin side. The settings are correct so I will sew from both sides next time. In this last test there was very little warning noise. It seemed that all the threads broke at the same time.

The forces are getting a little scary in my test site, so don't think I need to do any more testing on this. I also don't think a human body could survive that much stress.

|

|

|

21-11-2015, 12:35

21-11-2015, 12:35

|

#27

|

|

Writing Full-Time Since 2014

Join Date: Nov 2008

Location: Deale, MD

Boat: PDQ Altair, 32/34

Posts: 9,601

|

Re: Jack line stiching

Quote:

Originally Posted by Guy

The water knot won. The stitching failed again. This may be 4500lb test webbing but I think we are way over that. The thread seems to be failing most on the bobbin side. The settings are correct so I will sew from both sides next time. In this last test there was very little warning noise. It seemed that all the threads broke at the same time.

The forces are getting a little scary in my test site, so don't think I need to do any more testing on this. I also don't think a human body could survive that much stress. |

4500 is probably the minimum breaking strength, with the average about 4600-4700, from what I tested.

You should be able to get to 4500 pounds and see evidence of the webbing failing at the stitch line. The water knot will fail at about 3000 pounds, depending on the tape and the way the knot is tied (tail inside or outside).

That the stitching is failing with a load "crack" is a good sign. As Starzinger suggested, taking a close look as you approach the breaking point will generally give a good hint as to what failed first (maximum distortion).

But if the water knot won, you have your answer. Tie a knot, it is stronger and more dependable.

And yes, you do need that strength, because the stitching is going to loose strength in the sun and become abraded. The standards are set that high for very good reasons. Old gear does fail.

Just use the knot, well-set, with the tail secured.

---

But I understand the challenge and the joy of learning. High strength sewing and splices are a challenge.

|

|

|

21-11-2015, 16:10

21-11-2015, 16:10

|

#28

|

|

Senior Cruiser

Join Date: Aug 2009

Posts: 4,033

|

Re: Jack line stiching

^^ by the way - the figure 8 knot is stronger in webbing than the water knot (by about 15% of webbing tensile). It is a bit bulkier - but does at least give you another higher strength benchmark.

|

|

|

21-11-2015, 17:00

21-11-2015, 17:00

|

#29

|

|

Registered User

Join Date: Feb 2013

Location: Oregon

Boat: Seafarer36c

Posts: 5,563

|

Re: Jack line stiching

Quote:

Originally Posted by estarzinger

^^ by the way - the figure 8 knot is stronger in webbing than the water knot (by about 15% of webbing tensile). It is a bit bulkier - but does at least give you another higher strength benchmark.

|

I like to keep the jackline snug against the cabin. With either of those knots it's a pain to adjust them so the jackline is tighter, in fact you really can't. With a loop on the end you can have lashings which are easy to adjust.

|

|

|

|

|

| Thread Tools |

Search this Thread |

|

|

|

| Display Modes |

Rate This Thread |

Linear Mode Linear Mode

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Advertise Here

Recent Discussions Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vendor Spotlight Vendor Spotlight |

|

|

|

|

|

|

|

|

|